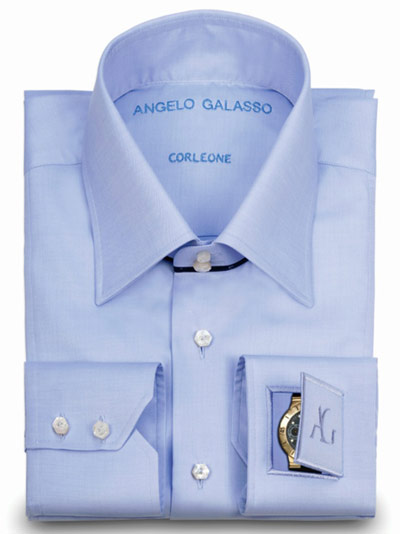

The Polso Orologio Shirt

In 1990, ANGELO GALASSO designed the Polso Orologio Shirt. His inspiration came from the former Fiat’s President Gianni Agnelli, who suffered from an allergy forcing him to wear his watch over the shirt cuff. In 1990, ANGELO GALASSO designed the Polso Orologio Shirt. His inspiration came from the former Fiat’s President Gianni Agnelli, who suffered from an allergy forcing him to wear his watch over the shirt cuff.

An ANGELO GALASSO shirt undertakes 85 different stages in its manufacturing process. The shirt is manufactured entirely by hand, adhering to the traditional Italian methods of fabric selection, sewing technique and assembly procedure. The shirt is constructed using ten stitches to the centimetre. The penultimate buttonhole is always horizontal, resulting in a streamlined look. The cuff is 12 cm long with the internal lining made of pure cotton, specially strengthened to avoid creasing.

To ensure the collar lies flat against the collarbone, the interlinings are glued and four collar stiffeners are sewn in, providing support and creating an utterly crisp finish. The entire shirt is sewn using the French seam method where the raw edges of the fabric are fully enclosed for a neater appearance. A tribute to the old tailoring traditions lies in the slight pleat of the shoulder line a unique feature of a hand-made shirt. Gussets, triangular pieces of cloth, are sewn on both sides of the shirt, bringing more breadth to its shape and providing the uppermost level of comfort.

In 2004, the Polso Orologio Shirt was exhibited at the Design Museum in London enriching ANGELO GALASSO's creations as work of art and timeless design.

The Jeans The Jeans

The manufacturing of the denim is rooted in the heritage of Genoese artisans, who produce a durable blue fabric Bordatto Ligure, mainly used for work-wear. Woven to provide sturdiness and easy aftercare, it also guarantees water resistance.

The Tie

The design process is also conveyed in the making of the neckties, which are back tacked with silk drawstrings and made inside-out using a special sewing machine called LIBA, allowing ties as long as 162 cm to be sewn.

The Shoes

The shoes seamlessly combine cutting-edge design with traditional craftsmanship, embracing the long-standing experience of Italian shoemakers. The intricate manufacturing process stems from the designer's passion for fine footwear and his admiration for the time-honoured skills of Italian shoemaking. After carefully selecting only the very best leather, the sole is allowed to age for 36 months in special dehumidified hothouses. The heel, consisting of five layers of leather, is then nailed on. To ensure the optimum grip a final rubber layer is added on. The twine and the yarn used for stitching are waxed by hand, a procedure that ensures durability and higher performance. The fit is calibrated to provide the feet with support and comfort. This expertise and thorough knowledge of the shoemaking art guarantees a completely unique and unrepeatable result. The shoes seamlessly combine cutting-edge design with traditional craftsmanship, embracing the long-standing experience of Italian shoemakers. The intricate manufacturing process stems from the designer's passion for fine footwear and his admiration for the time-honoured skills of Italian shoemaking. After carefully selecting only the very best leather, the sole is allowed to age for 36 months in special dehumidified hothouses. The heel, consisting of five layers of leather, is then nailed on. To ensure the optimum grip a final rubber layer is added on. The twine and the yarn used for stitching are waxed by hand, a procedure that ensures durability and higher performance. The fit is calibrated to provide the feet with support and comfort. This expertise and thorough knowledge of the shoemaking art guarantees a completely unique and unrepeatable result.

Angelo Galasso's key product includes the entire range from apparels to leather products like belts, bags and shoes. |